About sudden jump in QMAS signal

According to Horiba, there are three possible causes of the jump.

1. Low volume of ethanol.

The maximum set flow rate of the liquid mass flow controller is 1 g/min, and the control limit is 5% of the maximum flow rate. The current set flow rate is 0.046 g/min, which is below the control limit.

However, Horiba people confirmed that the electrical signal of the flow controller is OK, so it seems to be controllable.

2. The flow rate of the carrier gas is low.

The vaporizer is designed based on the assumption that the carrier gas flows at 500 mL/min, and it is possible that the ethanol sprayed atomically inside the vaporizer is not being carried.

3. Gas mixing is not working properly.

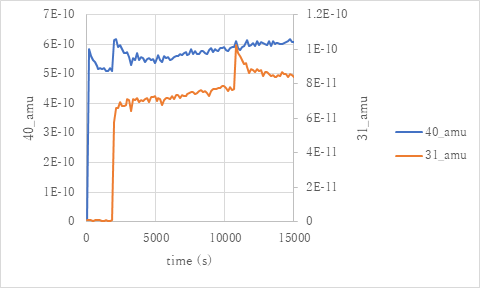

A figure summarizing the behavior of the Ar and EtOH signals is shown below. This shows that the amount of argon is strange (a jump is occurring on the argon side) for about 1200 seconds after ethanol begins to flow. During this time, condensation may have occurred in the gas mixer, and only argon and the small amount of ethanol remaining may have been sent to the QMS.

Investigations to determine the cause of the problem.

- 1. Increase the temperature setting of the vaporizer.

- Changed from 160°C to 180°C

- Currently in progress

- 2. Increase the ethanol flow rate

- 3. Increase the carrier gas flow rate

- 4. Increase the temperature of the heat block.

Another issue

There was an ethanol trap in front of the exhaust line of the ethanol vaporization system. The contents of the ethanol trap had not been discarded for 2-3 years, so approximately 1.5 L of liquid waste had accumulated and the trap was full.